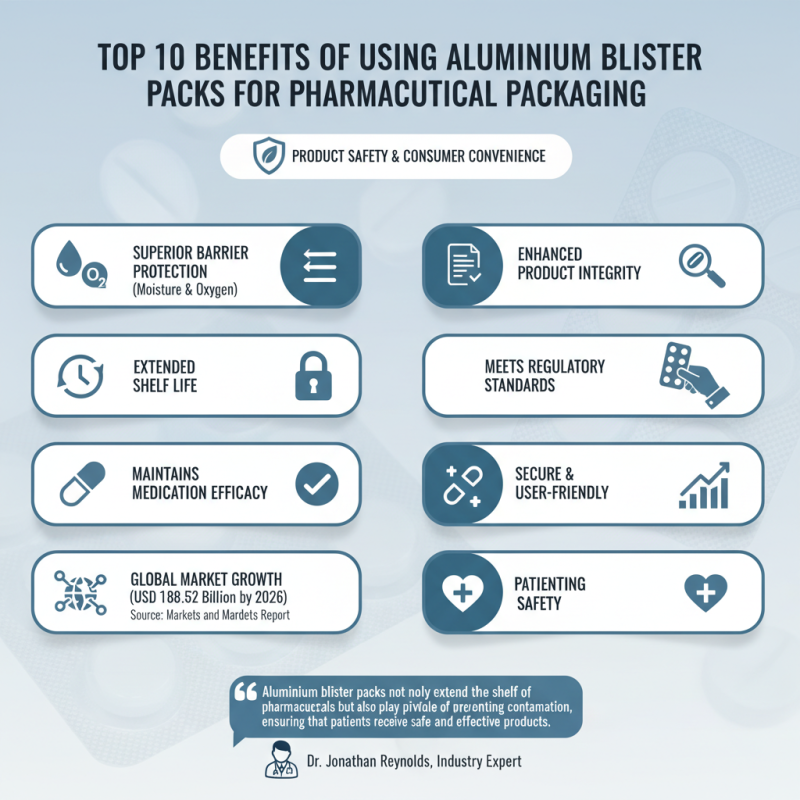

Top 10 Benefits of Using Aluminium Blister Packs for Pharmaceutical Packaging

Aluminium blister packs have emerged as a leading choice in the pharmaceutical packaging industry, boasting a multitude of benefits that enhance both product safety and consumer convenience. According to a report by Markets and Markets, the global pharmaceutical packaging market is projected to reach USD 188.52 billion by 2026, with aluminium blister packs contributing significantly to this growth. The versatility of aluminium allows for superior barrier protection against moisture and oxygen, which is crucial for maintaining the efficacy of medications.

Industry expert Dr. Jonathan Reynolds emphasizes the importance of these packaging solutions, stating, "Aluminium blister packs not only extend the shelf life of pharmaceuticals but also play a pivotal role in preventing contamination, ensuring that patients receive safe and effective products." As the demand for high-quality pharmaceutical packaging rises, the adoption of aluminium blister packs is increasingly viewed as a strategic move for manufacturers aiming to enhance product integrity while meeting regulatory standards. With their ability to provide secure and user-friendly packaging, aluminium blister packs are set to continue their upward trajectory in the market.

Key Advantages of Aluminium Blister Packs in Pharma Packaging

Aluminium blister packs are becoming increasingly popular in the pharmaceutical industry due to their unique advantages over traditional packaging methods. One of the key benefits of aluminium blister packs is their exceptional barrier properties. They provide an effective shield against moisture, light, and oxygen, which are critical factors that can compromise the integrity of pharmaceutical products. This protection not only extends the shelf life of medications but also ensures that they maintain their efficacy over time, thereby enhancing patient safety.

Moreover, aluminium blister packs offer convenience and dosage accuracy, making them particularly beneficial for patient compliance. Each compartment in the blister pack is designed to hold a single dose, allowing patients to easily visualize their medication schedule. This design minimizes the risk of dosage errors and helps patients manage their medications more effectively. Additionally, the tamper-evident feature of aluminium blister packs ensures that products remain secure until they reach the end-user, further enhancing safety and trust in the packaging. These combined advantages of barrier protection, convenience, and safety make aluminium blister packs an excellent choice for pharmaceutical packaging.

Top 10 Benefits of Using Aluminium Blister Packs for Pharmaceutical Packaging

Enhanced Drug Protection Through Aluminium Blister Technology

Aluminium blister packs have emerged as a preferred choice in pharmaceutical packaging, primarily due to their advanced protection capabilities. This specialized technology ensures that drugs are shielded from environmental factors like moisture, light, and air, which can compromise the efficacy of the medications. The layered structure of aluminium blister packs forms a robust barrier that minimizes the risk of contamination and degradation, enhancing both the safety and longevity of pharmaceuticals. This level of protection is crucial, particularly for sensitive formulations that require stringent maintenance of their chemical integrity.

Furthermore, the use of aluminium blister technology facilitates better dosage management and patient compliance. Each blister compartment is typically designed to contain a single dose, making it easy for patients to identify and administer their medication correctly. This system not only reduces the chances of accidental overdoses but also aids in tracking medication usage over time. The clear visibility of the medication also reassures patients and caregivers about adherence to treatment protocols, which is vital in achieving positive health outcomes. Overall, the enhanced drug protection offered by aluminium blister packs plays a pivotal role in promoting safer and more effective pharmaceutical practices.

Improved Patient Compliance with Easy-to-Use Blister Packs

Aluminium blister packs have revolutionized pharmaceutical packaging, enhancing patient compliance significantly. Their user-friendly design allows patients to easily access medications by simply pushing the pill through the foil backing. This straightforward mechanism reduces the likelihood of errors in dosage, fostering a sense of independence among patients, especially the elderly who may struggle with more complicated packaging. By ensuring that patients can manage their medication with confidence and ease, blister packs contribute to healthier medication habits and improved health outcomes.

When implementing blister packs in pharmaceutical packaging, here are a couple of tips to keep in mind. First, consider designing the blister pack with clearly labeled days or dates, allowing patients to easily track their medication schedule. This visual guide not only serves as a reminder to take medications but also helps to detect missed doses quickly. Secondly, ensure that the materials used are not only durable but also provide a moisture barrier to maintain the integrity of the medications. This prevents degradation and ensures patients receive effective products, which further reinforces their commitment to following prescribed treatments.

By prioritizing usability and protection, aluminium blister packs stand out as an optimal solution for promoting adherence to medication regimens.

Cost-Effectiveness of Aluminium Blister Packs in Pharmaceutical Industry

Aluminium blister packs have become increasingly popular in the pharmaceutical industry due to their remarkable cost-effectiveness. By utilizing these packs, manufacturers can achieve a high level of product protection while minimizing material waste. The design of blister packs allows for precise dosages, ensuring that consumers receive the correct amount of medication without excess packaging. This efficiency not only reduces production costs but also contributes to sustainable practices by lowering the environmental impact associated with packaging waste.

Moreover, aluminium blister packs provide excellent barrier properties against moisture, light, and oxygen, which are critical factors in maintaining the integrity of pharmaceutical products. This protective feature extends the shelf life of medications, thereby reducing losses that stem from expired or compromised products. Consequently, pharmaceutical companies experience decreased costs related to product recalls and wastage. The overall savings from reduced waste and extended product longevity allow companies to allocate resources more effectively, enhancing profitability without sacrificing quality.

Environmental Considerations and Recycling of Aluminium Packaging

The environmental impact of packaging materials has become a critical topic in the pharmaceutical industry. Aluminium blister packs, prominently known for their protective qualities, are also gaining attention for their recycling potential. According to a report by the Aluminium Association, 75% of all aluminium ever produced is still in use today, indicating the high recyclability of the material. This is particularly relevant in the context of pharmaceutical packaging, where the commitment to sustainability is increasingly important for both manufacturers and consumers.

In terms of recycling, aluminium can be reprocessed with relative ease. A study by the European Aluminium Foil Association emphasized that recycling aluminium saves up to 95% of the energy required to produce new aluminium from raw materials. This energy saving translates into a significant reduction in carbon emissions, making aluminium blister packs a more eco-friendly choice compared to other packaging options. Furthermore, the recycling process for aluminium is straightforward, as it can be collected alongside other recyclable materials, facilitating its return to the supply chain. By choosing aluminium blister packs, pharmaceutical companies not only enhance product safety and extend shelf life but also contribute positively to environmental sustainability efforts.

Related Posts

-

Top 10 Benefits of Aluminium Blister Packaging for Pharmaceutical Products

-

Top 10 Tips for Choosing the Right Aluminium Blister Pack for Your Products

-

Revolutionizing Cigarette Packaging through Advanced Aluminium Foil Solutions for Enhanced Freshness and Sustainability

-

2025 Top 5 Benefits of Aluminium Sachet Packaging for Modern Businesses

-

2025 How to Choose the Best Aluminum Stand Up Pouch for Optimal Product Shelf Life

-

Discover the Benefits of Using 250 ml Foil Containers for Food Storage and Meal Prep