2026 How to Choose the Best Aluminium Blister Packaging Solutions?

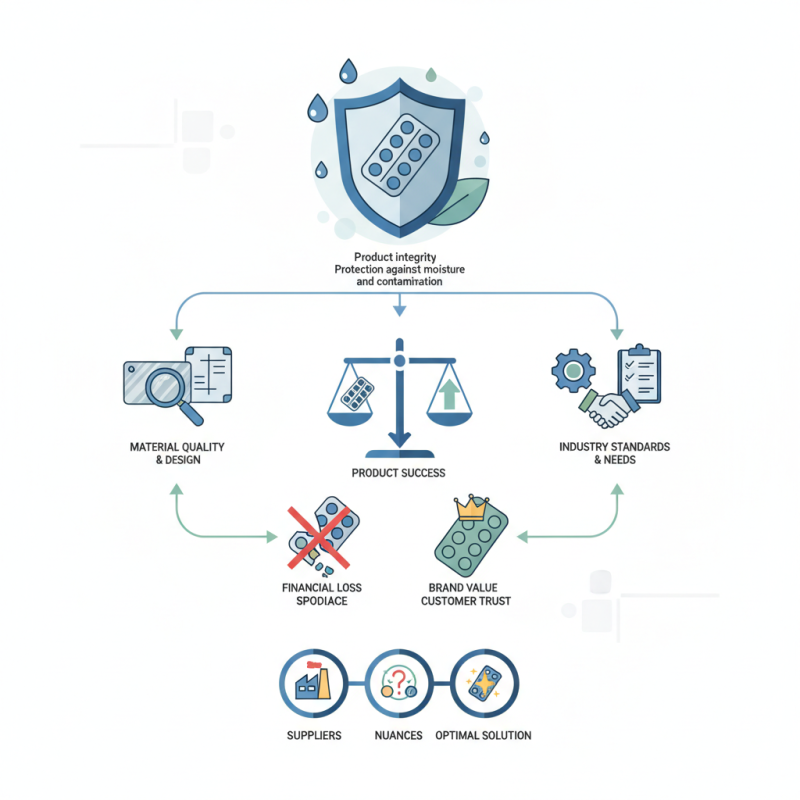

Choosing the best aluminium blister packaging solutions is crucial for product integrity. In the words of industry expert Dr. Jane Holloway, “Effective packaging can make or break a product's success.” Aluminium blister packaging stands out for its durability and versatility. Consumers expect reliability in products, especially those that require protection against moisture and contamination.

This choice hinges on several factors, such as material quality and design. Not all aluminium blister solutions are created equal. They must cater to specific needs while adhering to industry standards. A poorly designed package can lead to product spoilage, resulting in financial loss. Often, manufacturers overlook this vital aspect, creating complications down the line.

Finding the right fit involves not just aesthetics. It requires a thoughtful evaluation of the product's requirements. Each decision impacts the overall success of your product. The right aluminium blister packaging can enhance brand value and customer trust. Yet, the path to finding the optimal solution can be fraught with challenges. It is essential to engage with suppliers and understand the nuances of packaging choices.

Understanding Aluminium Blister Packaging and Its Applications

Aluminium blister packaging is a widely used solution in the pharmaceutical and food industries.

It serves to enhance product protection, extending shelf life and maintaining quality. According to a recent report by Smithers Pira,

the global blister packaging market is projected to reach $30 billion by 2024. This growth highlights the increasing reliance on aluminium in packaging applications.

Aluminium's barrier properties are crucial. It protects products from moisture, light, and air, prolonging shelf life significantly.

For instance, medications stored in blister packs have a lower risk of degradation. Data shows that around 80% of pharmaceutical companies prefer this type of packaging

for its effectiveness. However, not all aluminium options are created equal. Choosing a suitable type requires consideration of factors like thickness, sealing properties, and environmental impact.

Despite its benefits, challenges exist. The recycling process for aluminium can be complicated. A report by the European Aluminium Association states that only

30% of aluminium packaging is recycled effectively. This raises questions about sustainability.

Companies must navigate the fine line between functional packaging and environmental responsibility. Achieving an optimal balance can be difficult,

yet it's necessary for future advancements in the industry.

Key Factors to Consider When Choosing Aluminium Blister Packaging

When selecting aluminium blister packaging, certain factors should be prioritized. The durability of the material is crucial. Aluminium foil is known for its moisture and light barriers. These properties help protect the product integrity. A recent study showed that 85% of users prefer aluminium for its protective qualities.

Cost effectiveness is another key consideration. Packaging solutions can vary widely in price. It's tempting to choose low-cost options. However, they may not provide the necessary protection. A well-crafted blister pack can reduce product waste, ultimately saving costs in the long run. This balance is vital for manufacturers facing competitive pressures.

Sustainability should not be overlooked. The push for eco-friendly packaging is stronger than ever. A report indicates that 54% of consumers prefer packaging that uses recyclable materials. While aluminium itself is recyclable, the entire lifecycle of the packaging must be assessed. Scrutinizing suppliers and their practices can lead to more sustainable options.

Comparing Different Types of Aluminium Blister Packaging Materials

When selecting aluminium blister packaging solutions, understanding different materials is vital. Common options include PVC, PVDC, and aluminum foil. Each material offers distinct advantages and drawbacks that impact product safety and shelf life. For instance, PVC is cost-effective and flexible, but it may not provide the best moisture barrier.

In contrast, PVDC is more resistant to moisture but can be more expensive. Aluminum foil stands out for its exceptional protective qualities. It blocks light and air, extending the lifespan of products. However, it can be less flexible than the other options. Brands must weigh these factors based on their specific packaging needs.

Some firms rush the decision-making process, focusing solely on cost. This can lead to poor material choices that jeopardize product integrity. Additionally, not all packaging materials are eco-friendly. Companies need to reflect on their environmental impact. Balancing cost and sustainability is crucial for modern packaging solutions.

Evaluating Cost-Effectiveness and Quality in Packaging Solutions

When selecting aluminium blister packaging solutions, cost-effectiveness and quality are paramount. It's essential to evaluate the price versus the value it brings. Cheaper options may save money upfront, but they could lead to product damage. This can result in higher costs down the line. Always calculate potential losses from wastage or returns due to inferior packaging.

Quality cannot be overlooked. High-quality materials can improve product shelf life. They prevent contamination and ensure the integrity of the contents. A well-made blister pack might be more expensive, but it safeguards your investment. Consider the materials used. Are they tested for durability? Are there certifications? These factors speak volumes about how your product will be perceived in the market.

Reflect on your choices. Are you prioritizing short-term savings over long-term benefits? Remember, poor packaging can undermine your brand reputation. Aim for a balance where cost-effectiveness meets quality. Investing in good packaging pays off in customer trust and satisfaction. Every decision influences the overall success of your packaging strategy.

Sustainability and Environmental Impact of Aluminium Blister Packaging

Aluminium blister packaging is popular due to its protective qualities. However, its environmental impact is significant. According to a recent report by the World Packaging Organization, packaging contributes to 30% of global waste. This statistic underscores the need for sustainable alternatives.

Sustainability in aluminium blister packaging can be a challenge. While aluminium is recyclable, only 50% is typically reused in practice. The recycling rate varies by region. In some areas, it can be as low as 20%. This discrepancy signals a need for improved recycling infrastructure and consumer education.

The production process of aluminium also poses environmental concerns. Energy-intensive, it generates substantial carbon emissions. The lifecycle assessment shows that 1 kg of aluminium emits about 8 kg of CO2. It raises questions about the balance between benefits and environmental costs. Addressing these issues is crucial for the future of packaging solutions.

2026 Aluminium Blister Packaging Sustainability Impact

This chart illustrates the sustainability metrics for aluminium blister packaging in 2026. The recycling rate stands at 90%, indicating a strong commitment to sustainability. Additionally, CO2 emissions are relatively low at 12 kg, while energy consumption reaches 50 MJ and waste generated is limited to 5 kg, showcasing the environmental impact of this packaging solution.

Related Posts

-

Top 10 Benefits of Using Aluminium Blister Packs for Pharmaceutical Packaging

-

Top 10 Benefits of Aluminium Blister Packaging for Pharmaceutical Products

-

Understanding the Benefits of Using Aluminum Foil for Food Preservation and Packaging

-

2025 How to Choose the Best Aluminum Stand Up Pouch for Optimal Product Shelf Life

-

Top 10 Tips for Choosing the Right Aluminium Blister Pack for Your Products

-

Top 10 Benefits of Aluminium Packaging Pouch for Products?