Top 10 Benefits of Aluminium Packaging Pouch for Products?

Aluminium packaging pouches have revolutionized the packaging industry. These versatile pouches offer numerous advantages for product preservation, aesthetics, and sustainability. According to a recent report by Smithers Pira, the global demand for aluminium packaging is expected to increase by 4% annually through 2027. This surge highlights the efficacy of aluminium in modern packaging solutions.

Expert Helen J. Browning, a leading figure in the industry, states, “Aluminium packaging pouches not only improve shelf life but also enhance product appeal.” This statement reflects the growing recognition of the benefits these pouches provide. They are lightweight, durable, and provide an excellent barrier against moisture, oxygen, and light. However, it's crucial to consider the environmental impact of aluminium sourcing and recycling.

Despite the advantages, the system for recycling aluminium pouches poses challenges. Industry leaders suggest that improvements are necessary for efficient recycling processes. While aluminium packaging pouches are instrumental for many products, ongoing dialogue about their environmental footprint is essential. Balancing convenience and sustainability remains a pressing issue in this evolving sector.

Benefits of Lightweight Nature of Aluminium Packaging Pouches

Aluminium packaging pouches are gaining popularity due to their lightweight nature. This feature makes them easy to handle and transport. Unlike heavier alternatives, they reduce shipping costs significantly. The reduced weight also means less energy consumption during transportation. It's a win-win for companies looking to optimize their logistics.

Moreover, these pouches offer superior barrier properties. They protect products from moisture, light, and oxygen. However, the lightweight aspect can sometimes lead to concerns about durability. Buyers may wonder if a lighter pouch can withstand rough handling. Manufacturers need to address these worries while maintaining the benefits of lightness.

In addition, the flexibility of aluminium pouches is noteworthy. They can be designed in various shapes and sizes. This adaptability allows brands to create appealing packaging that stands out. However, some designs may not provide adequate protection for delicate items. Striking a balance between design and functionality is essential.

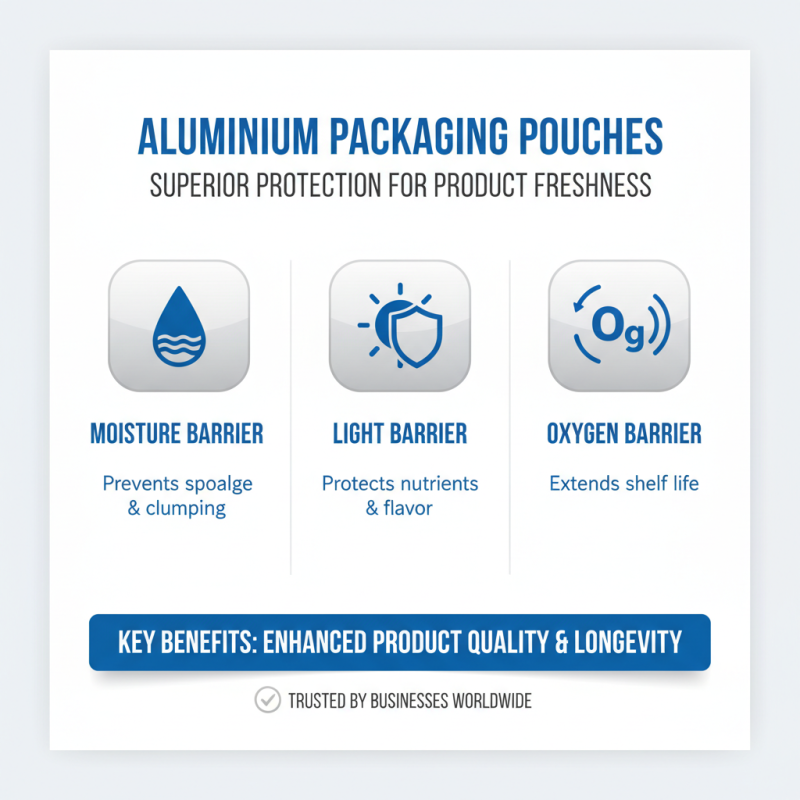

Superior Barrier Protection Against Moisture, Light, and Oxygen

Aluminium packaging pouches are gaining popularity for their impressive barrier properties. They offer superior protection against moisture, light, and oxygen. This protection helps to preserve the integrity and freshness of products. For many businesses, maintaining product quality is essential. Aluminium pouches achieve this goal effectively.

The materials used in aluminium pouches act as a shield. They prevent moisture from entering, which can lead to spoilage. Light exposure can degrade sensitive contents, and aluminium blocks this efficiently. Oxygen is another enemy of product quality. With the right sealing techniques, aluminium pouches limit oxygen exposure, extending shelf life.

However, some may overlook the importance of choice. Not all aluminium pouches are created equal. Quality can vary significantly. This requires careful consideration during selection. Companies must weigh the potential benefits against costs. A well-chosen pouch can save money in the long run, but a poor choice can lead to waste. These decisions can have lasting impacts on product sustainability and customer satisfaction. Each detail matters.

Sustainability: The Recyclability of Aluminium Packaging Pouches

Aluminium packaging pouches are gaining traction for their excellent recyclability. Data reveals that about 75% of all aluminium ever produced is still in use today. This long lifespan is a testament to aluminium's unique properties. The closed-loop recycling process allows these pouches to be repurposed repeatedly without losing quality. This is a significant advantage over other materials, which may degrade after recycling.

However, there are challenges to address. While aluminium pouches are recyclable, only 20% of the global aluminium packaging is collected for recycling. Many consumers still dispose of these pouches in general waste. This oversight leads to valuable resources being lost. Raising awareness about proper disposal methods is crucial for maximizing aluminium's sustainability potential.

Furthermore, the production of aluminium does have environmental impacts. Mining bauxite, the primary ore of aluminium, contributes to habitat destruction. The energy-intensive processing also emits greenhouse gases. Despite these issues, the recyclability and durability of aluminium packaging pouches present significant opportunities for reducing waste in the long run. Proper management and education can enhance their overall benefits to our planet.

Top 10 Benefits of Aluminium Packaging Pouch for Products

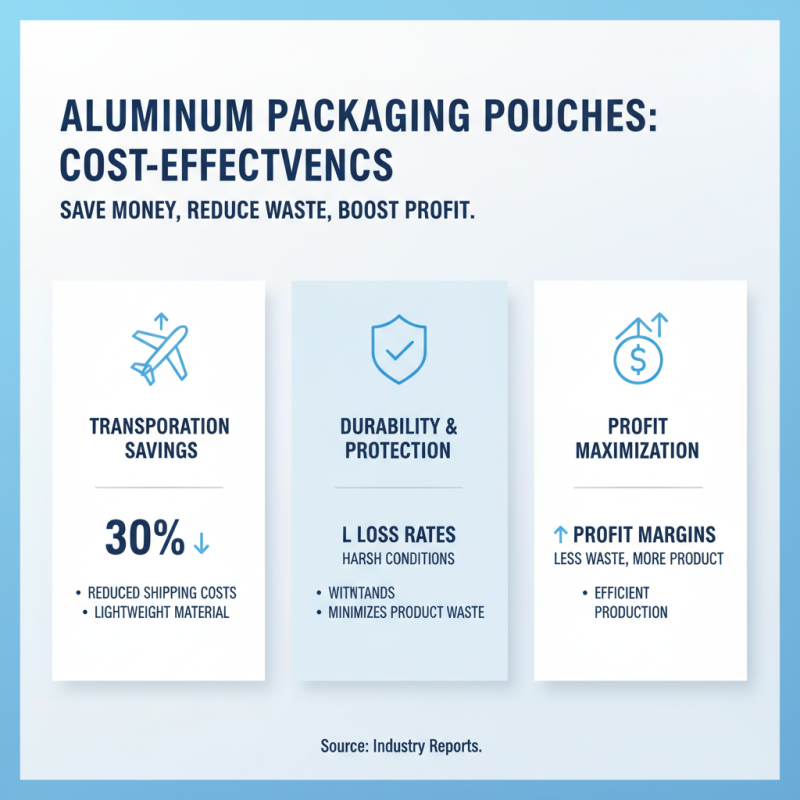

Cost-Effectiveness in Production and Transportation of Aluminium Pouches

Aluminium packaging pouches offer significant cost-effectiveness in production and transportation. According to industry reports, aluminium pouches are lightweight. This reduces shipping costs by up to 30%. Their durability means they can withstand harsh transportation conditions, cutting loss rates. This is crucial for businesses aiming to minimize waste and maximize profit margins.

In terms of production, aluminium pouches require less material than traditional packaging. This conserves resources and reduces overall production costs. Data suggests that manufacturers save up to 20% in material costs when opting for aluminium pouches. However, not all manufacturers are fully utilizing these benefits. Some still hesitate to shift from conventional materials, citing concerns over initial investments.

The manufacturing process for aluminium pouches is also more efficient. Their design allows for high-speed filling and sealing. This can boost production rates significantly. Nevertheless, there are challenges. The initial setup costs for aluminium pouch machinery can deter smaller companies. These factors reveal that while the benefits are clear, careful consideration is needed before making the switch.

Versatility in Design and Application for Various Product Categories

Aluminium packaging pouches have transformed product packaging across multiple industries. Their versatility allows for customized designs tailored to different categories, from food to cosmetics. According to a recent study, nearly 60% of consumers prefer products in vibrant, standout packaging. Aluminium pouches can be printed with eye-catching graphics, enhancing brand visibility.

These pouches are not only aesthetic but functional. They offer excellent barrier protection against moisture and light, ensuring product integrity. Research indicates that products packaged in aluminium maintain freshness longer. This is critical for food items which can spoil quickly. However, not all designs consider sustainability. While aluminium is recyclable, the production process can be energy-intensive.

The adaptability of these pouches is noteworthy. They can be made in various sizes and shapes, fitting diverse products like snacks, detergents, or medical supplies. Despite their advantages, some businesses may overlook the necessity for proper sealing methods, risking product safety. As the demand for flexible packaging grows, brands face the challenge of balancing innovation and sustainability.

Related Posts

-

How Aluminium Packaging for Food Enhances Freshness and Reduces Waste: An In-Depth Look

-

Top 10 Benefits of Aluminium Sachet Packaging for Products in 2023

-

How to Choose the Best Aluminium Pouch for Food Storage and Preservation

-

Exploring the Benefits of Laminated Aluminium Foil Packaging for Food Preservation

-

What is Aluminium Foil Packaging for Food and Its Benefits?

-

Understanding the Benefits of Using Aluminum Foil for Food Preservation and Packaging