Why is Aluminium Foil the Best Choice for Cigarette Packaging Solutions

Aluminium foil for cigarette packaging stands out as the superior choice for protecting the integrity and quality of tobacco products in a highly competitive market. According to a report by Smithers Pira, the global demand for cigarette packaging is projected to reach approximately 2.9 million tons by 2024, with aluminium foil continuing to occupy a significant share due to its unique properties. This material not only provides an effective barrier against moisture, light, and oxygen, but also extends the shelf life of cigarettes, ensuring that consumers enjoy the best flavor and freshness until the moment of use.

Furthermore, studies indicate that the use of aluminium foil can reduce the likelihood of product deterioration, which is critical in maintaining brand reputation and customer loyalty. The lightweight nature of aluminium also contributes to lower shipping costs and reduced environmental impact, aligning with the industry's growing focus on sustainability. In addition to its protective qualities, aluminium foil offers excellent printability, which allows manufacturers to create visually appealing packaging that captures consumer attention while adhering to regulatory requirements. Overall, the adoption of aluminium foil for cigarette packaging not only enhances product quality but also supports sustainable practices and market competitiveness.

The Unique Properties of Aluminium Foil in Cigarette Packaging

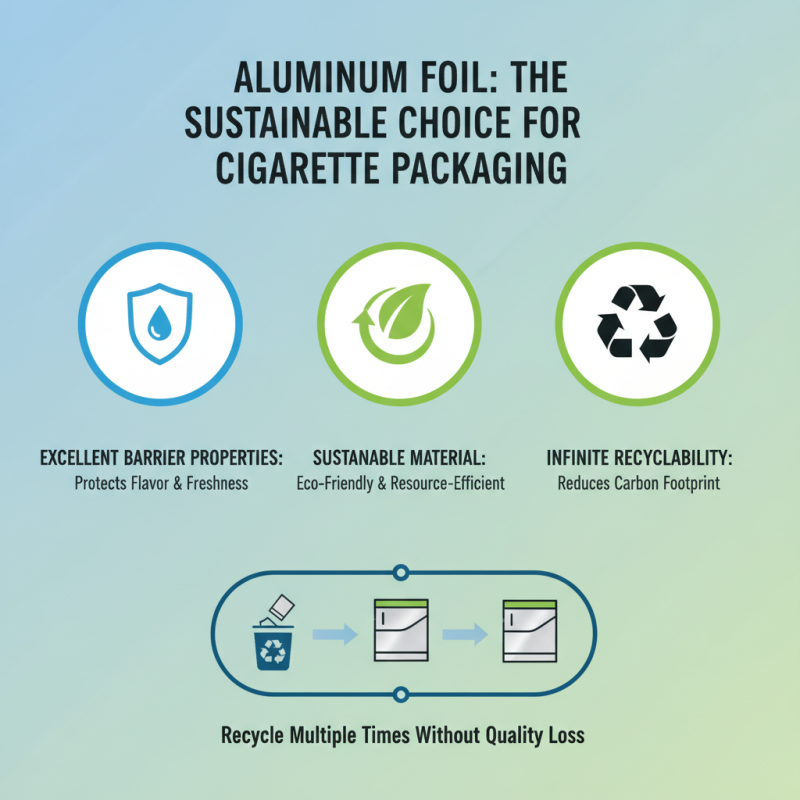

Aluminium foil has emerged as the preferred choice for cigarette packaging due to its unique properties that enhance product protection and consumer experience. One of its most significant advantages is its excellent barrier properties. According to a report by the European Aluminium Foil Association, aluminium foil can effectively block light, moisture, oxygen, and contaminants, preserving the freshness and integrity of the product for an extended period. This characteristic is crucial in maintaining the flavor and aroma of tobacco, which can be adversely affected by exposure to air and humidity.

Additionally, aluminium foil's malleability allows it to conform tightly to the shape of the product, reducing the potential for damage during transportation and handling. A study published in the Packaging Journal highlighted that packaging films made of aluminium foil can contribute to a significant reduction in product spoilage, with a reported decrease of up to 30% in waste for tobacco products. Furthermore, the recyclability of aluminium foil aligns with the growing demand for sustainable packaging solutions, as it can be recycled without loss of quality, effectively reducing the environmental impact associated with cigarette packaging.

These properties collectively make aluminium foil a superior choice in the competitive landscape of cigarette packaging, ensuring that products not only remain intact and secure but also meet the increasing consumer expectations for quality and environmental responsibility.

Benefits of Aluminium Foil Over Other Packaging Materials

Aluminium foil has emerged as a superior choice for cigarette packaging, primarily due to its unique properties that stand out against alternative materials. One of its most significant advantages is its excellent moisture barrier. Cigarettes are highly sensitive to humidity, which can affect their freshness and overall quality. Aluminium foil effectively prevents moisture from permeating the packaging, ensuring that the product remains dry and maintains its flavor for an extended period. This is crucial for manufacturers aiming to deliver a consistently high-quality product to consumers.

Additionally, aluminium foil is known for its ability to provide a strong barrier against light and oxygen. These elements can degrade the components of tobacco, leading to a decrease in quality. By blocking out light and limiting oxygen exposure, aluminium foil helps to preserve the integrity of the cigarettes more effectively than paper or plastic options. Furthermore, its lightweight nature contributes to reduced transportation costs, making it a practical choice for manufacturers. The adaptability of aluminium foil allows it to be easily printed and shaped, which enhances branding opportunities while ensuring that functional properties are not compromised.

Benefits of Aluminium Foil for Cigarette Packaging

Impact of Aluminium Foil on Cigarette Freshness and Flavor

Aluminium foil has emerged as the premier choice for cigarette packaging due to its unique properties that significantly impact cigarette freshness and flavor. One of the critical advantages of aluminium foil is its excellent barrier capabilities. According to industry reports, aluminium foil can reduce the permeability to moisture and oxygen by up to 99%, compared to other packaging materials. This exceptional barrier preserves the integrity of the cigarettes, ensuring that they remain fresh and flavorful for an extended period. Additionally, the reflective surface of aluminium foil helps protect the contents from light exposure, which is known to degrade flavor compounds over time.

To maximize the preservation of cigarette flavor, it is essential to consider proper storage methods. TIPS: Keeping cigarette packs sealed in their original aluminium packaging until ready for use can significantly prolong their shelf life. Furthermore, storing them in a cool, dry place away from direct sunlight will help maintain the optimal freshness and flavor profile.

Moreover, studies indicate that the use of aluminium foil in cigarette packaging influences consumer perception positively. A fresh cigarette not only enhances satisfaction but also contributes to a better overall smoking experience. TIPS: Choosing products with sound packaging can significantly impact enjoyment; always check for the integrity of the packaging before making a purchase. Manufacturers focusing on aluminium foils for their packaging reflect the industry’s commitment to quality and consumer satisfaction.

Sustainability and Recycling of Aluminium Foil in Packaging

Aluminium foil stands out as the ideal choice for cigarette packaging not only due to its excellent barrier properties but also because of its sustainability and recycling potential. In today’s environmentally conscious world, the use of sustainable materials is crucial. Aluminium foil can be recycled multiple times without losing its quality, making it a more responsible choice compared to other packaging materials. This recycling capability contributes significantly to resource conservation and reduces the carbon footprint associated with manufacturing new materials.

Tips for maximizing the sustainability of aluminium foil include ensuring that it is clean and free from food residues before recycling, as this can enhance the recycling process. Additionally, consumers can support initiatives that promote the recycling of aluminium by participating in local recycling programs and advocating for the use of recycled materials in packaging. By choosing aluminium foil, companies not only benefit from its protective qualities but also align with environmentally friendly practices that resonate with increasingly eco-aware consumers.

The process of recycling aluminium foil is energy-efficient; it requires only a fraction of the energy needed to produce new aluminium from raw materials. This aspect not only fosters a circular economy but also highlights the importance of consumer involvement in sustainability efforts. By prioritizing aluminium foil in cigarette packaging, businesses can contribute to a more sustainable future while delivering a product that meets both functional and environmental needs.

Future Innovations in Aluminium Foil for Cigarette Packaging Solutions

As the demand for innovative and effective packaging solutions continues to rise, aluminium foil has emerged as a leading choice for cigarette packaging due to its unique properties. The future of aluminium foil in this sector is poised for remarkable advancements. According to a report from Smithers Pira, the global demand for flexible packaging, including aluminium foil, is expected to grow at a CAGR of 4.3% through 2024. This growth is driven by increasing consumer preferences for sustainable and recyclable packaging materials, where aluminium foil stands out due to its inertness and superior barrier properties.

Innovations in aluminium foil technology aim to enhance its functionality further. For instance, advancements in manufacturing processes have led to the development of thinner foils with better strength and durability, enabling brands to reduce material usage while maintaining product integrity. Furthermore, the integration of smart packaging technologies, such as moisture indicators and anti-counterfeiting features, is on the horizon. A report by MarketsandMarkets indicates that the smart packaging market is expected to reach $46 billion by 2025, showcasing a significant shift towards tech-enhanced solutions in packaging, including aluminium foil. These innovations not only provide enhanced protection but also align with sustainability goals, making aluminium foil an even more attractive choice for cigarette packaging in the future.

Why is Aluminium Foil the Best Choice for Cigarette Packaging Solutions - Future Innovations in Aluminium Foil for Cigarette Packaging Solutions

| Feature | Benefit | Innovation Potential |

|---|---|---|

| Barrier Properties | Protects against moisture, light, and air, preserving freshness. | Development of multilayer foils with enhanced barrier technologies. |

| Recyclability | Aluminium is highly recyclable, reducing environmental impact. | Innovations in recycling processes to increase efficiency. |

| Customization | Can be printed with attractive designs and logos. | Advancements in printing technology for high-quality graphics. |

| Durability | Resistant to tearing and puncturing during handling. | Research into stronger alloys and treatments to enhance durability. |

| Lightweight | Reduces shipping costs due to lower weight. | Innovations in thin foil technology that maintains strength. |

Related Posts

-

Top Benefits of Using Aluminium Stand Up Pouches for Sustainable Packaging Solutions

-

Why Laminated Aluminium Foil Packaging is Essential for Food Preservation and Sustainability

-

Understanding the Benefits of Using Aluminum Foil for Food Preservation and Packaging

-

How Aluminium Packaging for Food Enhances Freshness and Reduces Waste: An In-Depth Look

-

What is Aluminium Foil for Food Packaging and Its Benefits for Preservation

-

Top 10 Benefits of Aluminium Blister Packaging for Pharmaceutical Products